General

Commercial reagents, standards, and solvents were purchased from Sigma Aldrich (Shanghai, China), Meryer Chemicals (Shanghai, China), Aladdin Reagents (Shanghai, China), J&K Chemicals (Beijing, China), and TCI Chemicals (Shanghai, China), and used without further purification. All codon-optimized genes and primers used in this study were listed in Supplementary Date 1.

Fermentation medium and conditions

A single colony of recombinant E. coli strain was cultivated overnight (10−12 h, 37 °C) in LB medium (10 g·L–1 peptone, 5 g·L–1 yeast extract, and 10 g·L–1 NaCl; pH 7.0) with appropriate antibiotics (50 μg·mL-1 kanamycin) and used as the inoculum (1%). The culture was then transferred into 200 mL 2×YT medium (10 g·L-1 yeast extract, 16 g·L–1 peptone, 5 g·L–1 NaCl; pH 7.0) containing appropriate antibiotics in a 500 ml flask. When the OD600 of the culture broth reached 0.6-0.8, isopropyl β-D-1-thiogalactopyranoside (IPTG) was added to a final concentration of 0.2 mM to induce gene expression. The cells were inducted at 16 °C for 16 h and collected by centrifugation (8000 × g, 10 min).

Enzyme purification

The cell pellet was resuspended in 30 ml washing buffer (50 mM Na2HPO4, 150 mM NaCl, pH 8.0) containing a protease inhibitor and subsequently lysed by high pressure homogenizer. The lysed cells were incubated with DNase I (final concentration 0.1 mg·ml−1) for 30 min at 4 °C. After removing cell debris by centrifugation (10,000 r.p.m., 30 min, 4 °C). The cleared lysate was loaded on a Strep-Tactin column (Strep-Tactin Superflow high capacity), incubated for 60 min at 4 °C, and the protein was purified according to the manufacturer’s guidelines. Proteins were desalted using 10DG desalting columns (Bio-Rad) with PBS pH 10.0 and analysed by SDS–PAGE. When it is necessary to perform protein crystallization experiments, the subsequent experiments were performed on an ÄKTA pure system (GE Healthcare) with a HisTrap HP column (5 ml, GE Healthcare). Protein concentration of purified enzyme was measured by detecting absorbance at 280 nm using a NanoPhotometer N50 spectrophotometer and considering the calculated extinction coefficients with the ExPASy ProtParam Tool.3. All purification operations were conducted at 4°C when necessary. The uncropped and unprocessed gels scans were provided in the Source Data and Supplementary Information.

HPLC analysis

Analysis of the concentration of adduct 3 was carried out using Waters Alliance e2695 HPLC (Waters Co., USA) with UV detector at 269 nm. Analysis of the concentration of adduct 3a-3g was carried out using Waters Alliance e2695 HPLC (Waters Co., USA) with UV detector at 254 nm. Column: Agilent SB-C18 (150×4.6 mm, 5 μm), mobile phase: acetonitrile: H2O (0.7% HAc) = 30:70, flow rate: 1 mL·min-1, temperature: 25 °C. Peaks were assigned by comparison to chemically synthesized standard.

The separation and purification of adduct 3 was carried out using preparative high performance liquid chromatography Waters 2545 Binary Gradient Module (Waters Co., USA) with a Waters 2767 Sample Manager, and the UV detector at 269 nm. Column: CST Daiso C18 (250 × 20 mm, 10 μm, 12 nm), mobile phase: acetonitrile: H2O (0.7% HAc) = 30:70, flow rate: 10 mL·min–1, temperature: 25 °C.

The stereoselectivity of MBH adduct 3 were determined using Waters Alliance e2695 HPLC (Waters Co., USA) with UV detector at 269 nm. The stereoselectivity of MBH adduct 3a-3g were determined using Waters Alliance e2695 HPLC (Waters Co., USA) with UV detector at 254 nm. Column: DAICEL CHIRALPAK IC (250 × 4.6 mm, 5 μm), flow rate: 1 mL·min–1, temperature: 25 °C, mobile phase: n-hexane/isopropanol=90/10 (v/v). Peaks were assigned by comparison to the results of BH32.1423.

GC and GC-MS analysis

The concentrations of 3 and 4 were determined by using a GC (GC-2030, SHIMADZU, Japan) with a column (SH-5, 15 m × 0.25 mm × 0.1 μm; SHIMADZU). The GC analysis conditions were as follows: injector 310 °C, and oven 45 °C, hold 2 min, 10 °C min-1 to 280 °C, hold 10 min.

The identification of adducts (3, 3a–3g) were determined by using a GC-MS (Trace1310-TSQ8000, Thermo Scientific, USA) with a column (TG-5 30 m×0.25 mm×0.25 μm). The GC analysis conditions were as follows: injector 270 °C, ion source temperature 300 °C, and oven 80 °C, 15 °C min–1 to 280 °C, hold 8 min. Sample processing: 300 μL reaction samples, extraction experiments were performed after the addition of an equal volume of ethyl acetate, centrifuged at 14,000 × g for 10 min, filtered by 0.22 μm filter membrane, and then determined by GC-MS detection (according to the situation or ethyl acetate appropriate dilution), for determining the content of the product. Three times of biological replicates.

Activity assay

The activity of MBHase was measured by HPLC. The assay mixture contained 300 µL PBS buffer (pH 10.0), including 1 mM 2, 5 mM 1 and 30 μM purified protein. Reactions were conducted in triplicate and incubated at 25 °C and 220 rpm for 10 h and started by addition of the enzyme solution. The reaction was terminated with equal volume of 1 M HCl, centrifuged at 14,000 × g for 10 min, filtered by 0.22 μm filter membrane, and then determined by HPLC. One unit of specific activity is defined as the amount of adduct 3 (in nmol) that can be produced by one unit of enzyme in per minute under standard conditions.

Determination methods for the yield

The molar concentration of the product was quantified using the external standard method. Subsequently, the yield of different products were determined using

$${{{{{\rm{yield}}}}}}= \frac{C\left({{{{{\rm{Product}}}}}}\right) * {{{{{\rm{dilutionfactor}}}}}}}{C\left({{{{{\rm{substrate}}}}}}\right)} * 100 \%,\\ C \!: {{{{{\rm{molar}}}}}} \,{{{{{\rm{concentration}}}}}}.$$

(1)

Kinetic characterization

Initial velocity (V0) versus [4-nitrobenzaldehyde] kinetic data were measured using strep-tagged purified enzyme (30 µM), a fixed concentration of 1 (5 mM) and varying concentrations of 2 (0.5–35 mM). Reactions were performed in PBS pH 10.0 with 3% methanol and were incubated at 25 °C with shaking (220 r.p.m.) for 12 h. V0 versus [2-cyclohexen-1-one] kinetic data were measured using a fixed concentration of 2 (4 mM) and varying concentrations of 1 (0.5–10 mM) using the enzyme concentrations and buffer conditions described above. Samples were quenched with 1 vol. of 1 M HCl and analyzed by HPLC. The Km and kcat values were calculated by nonlinear regression according to the Michaelis–Menten equation using GraphPad Prism software.

Mass spectrometry

Purified protein samples were labeled at 5 mM 2-cyclopentenone for 2 h and buffer-exchanged into PBS (pH 10.0) using a 10 k MWCO Vivaspin unit (Sartorius) and diluted to a final concentration of 0.2 μM and then add 0.2% acetic acid. MS was performed using LTQ-Orbitrap Velos system, mass range: 500–1500, max inject time: 10 ms, resolution: 30000, sheath gas flow rate: 30, aux gas flow rate: 5, sweep gas flowrate: 1, capliary temp: 275°C, S-Lens RF Level: 69%, flow rate: 2 μL·min−1, record: 10 min. The resulting multiply charged spectrum was analyzed and deconvoluted using Unidec software. The total number of sample and control are both one, three times of biological replicates, the control are GkOYE.8C26A.

LC-MS

detection was performed on a Sciex LC coupled to a triple quadrupole trap mass spectrometer (QTRAP 5500, AB Sciex, USA) (Q-TRAP-MS) with electrospray ionization (ESI) in negative mode. The HPLC analysis was performed on the BEH C18 column (2.5 μm, 2.1 × 50 mm; Waters) at a temperature of 40 °C. The mobile phase was a mixture of two solvents: A- water (0.1% FA) and B- acetonitrile. The optimized linear gradient system was as follows: 0 min, 95 % A; 0–1 min to 95% A; 1–5 min, to 5% A; 5–7 min, 5% A; 7–10 min to 95% A. The autosampler was set to 4 °C. The injection volume was 2 μL, and the flow rate was 300 μL/min. The injection needle was washed after each injection with acetonitrile. The instrument parameters were as follows: ion spray voltage (IS): 5500 V; temperature: 550 °C; nebulizer gas (GS1): 60 psi; turbo gas (GS2): 60 psi; curtain gas (CUR): 35 psi; and collision gas (CAD): medium. Instrument control and data integration were performed using Analyst® Software Version 1.6.2. Sample processing: Protein samples were boiled at 100 °C for 10 min and centrifuged at 14,000 × g for 10 min, the supernatant was collected and filtered through 0.22 μm filter membrane and then determined by LC-MS detection (according to the situation or ethyl acetate appropriate dilution). The total number of sample and control are 1 and 2, respectively. three times of biological replicates, the controls are the protein of wild type of GkOYE and the commercial reagent FMN.

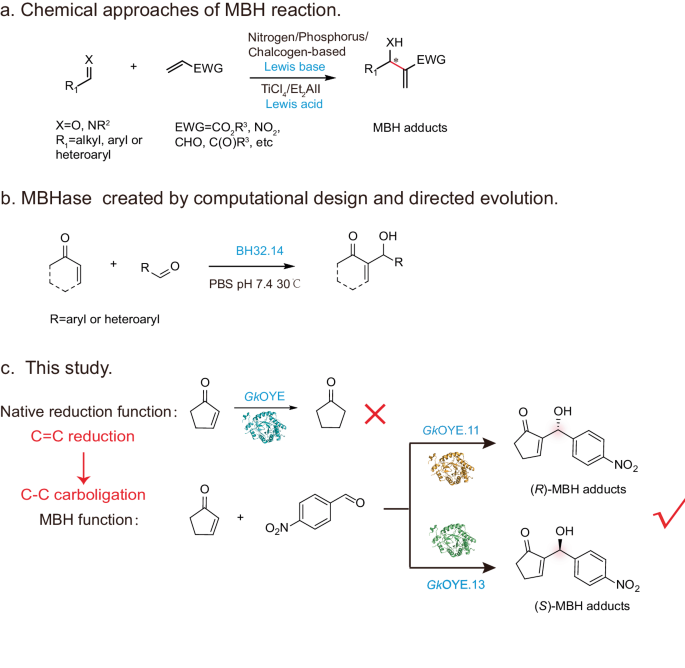

Biotransformation procedures. For the reduction reaction catalyzing by GkOYE

Reactions were performed in 300 μL PBS buffer (pH 7.4) with 5 mM 1, 1 mM NADPH, 100 μM purified protein and 1% methanol as cosolvent. Reactions were incubated at 25 °C and 220 rpm for 8 h. The solution was extracted with the same volume ethyl acetate (EtOAc). The resulting solution was dried by Na2SO4 and filtered through 0.22 μm membrane filters. Then the yield determined via GC.

For the MBH reaction catalyzing by GkOYE and mutants

For the product 3, 3a-3g, reactions were performed in 300 μL PBS buffer (pH 10.0) with 5 mM 1,1a, 1 mM 2, 2a-2i, 100 μM purified protein and 3% methanol as cosolvent. Reactions were incubated at 25 °C and 220 rpm for 40 h. The reaction was terminated with equal volume of 1 M HCl, centrifuged at 14,000 × g for 10 min, filtered by 0.22 μm filter membrane, and then determined by HPLC. For the detection of stereoselectivity of MBH adducts. The solution was extracted with the same volume ethyl acetate (EtOAc). The resulting solution was dried by Na2SO4 and filtered through 0.22 μm membrane filters. Then the stereoselectivity was determined via HPLC with chiral column.

All the experiments were carries out at least in duplicate. The above products were further identified by nuclear magnetic resonance (NMR) analysis and shown in Supplementary Fig. 13–22. The representative HPLC chromatograms are shown in Supplementary Fig. 23–44. The representative GC-MS chromatograms are shown in Supplementary Fig. 45–54.

Preparation of racemic products standards

2-(hydroxy(4-nitrophenyl)methyl)cyclopent-2-en-1-one (3) was separation and purification using preparative high performance liquid chromatography. The instrument and method use Waters 2545 Binary Gradient Module (Waters Co., USA) with a Waters 2767 Sample Manager, and the UV detector at 269 nm. Column: CST Daiso C18 (250×20 mm, 10 μm, 12 nm), mobile phase: acetonitrile: H2O (0.7% HAc) = 30:70, flow rate: 10 mL·min–1, temperature: 25 °C. The spectral data are consistent with literature values41. 1H NMR (600 MHz, Chloroform-d) δ 8.19 (d, J = 8.4 Hz, 2H), 7.57 (d, J = 8.4 Hz, 2H), 7.31 (s, 1H), 5.66 (s, 1H), 3.74 (s, 1H), 2.66–2.59 (m, 2H), 2.52 – 2.42 (m, 2H). 13C NMR (151 MHz, Chloroform-d) δ 209.45, 160.07, 148.68, 147.58, 146.85, 127.21, 123.83, 69.02, 35.26, 26.96. MS (EI): m/z calcd for C12H11NO4: 233.07; found: 233.1.

General procedure for the preparation of racemic product standards (3a–3g) was refer to the literature23. Arylaldehyde (1.5 mmol, 1.5 equiv.), cyclic enone (3 mmol, 3.0 equiv.), KOH (1 mmol, 1.0 equiv.) and imidazole (1 mmol, 1.0 equiv.) were stirred in 1 M NaHCO3 (2 ml) and THF (2 ml) for 48 h at room temperature. The reaction was acidified with 1 M HCl and extracted with EA (3 × 50 ml). The organic layer was dried over MgSO4 filtered, and the solvent was removed in vacuo to give the crude product. The crude product was purified by silica gel chromatography (PE:EA = 2:1).

4-(hydroxy(5-oxocyclopent-1-en-1-yl)methyl)benzonitrile (3a)

The crude product was purified by flash chromatography (PE:EA = 2:1) to give the product (101.7 mg, 31.8%).The spectral data are consistent with literature values42. 1H NMR (600 MHz, Chloroform-d) δ 7.63 (d, J = 8.4 Hz, 2H), 7.51 (d, J = 8.4 Hz, 2H), 7.30 (t, J = 2.7 Hz, 1H), 5.60 (s, 1H), 3.70 (s, 1H), 2.64–2.56 (m, 2H), 2.49 – 2.41 (m, 2H). 13C NMR (151 MHz, Chloroform-d) δ 209.38, 159.90, 146.93, 146.78, 132.41, 127.09, 118.80, 111.64, 69.17, 35.25, 26.91. MS (EI): m/z calcd for C13H11NO2: 213.08; found: 213.1.

2-((4-chlorophenyl)(hydroxy)methyl)cyclopent-2-en-1-one (3b)

The crude product was purified by flash chromatography (PE:EA = 2:1) to give the product (75.5 mg, 22.7%). The spectral data are consistent with literature values43. 1H NMR (600 MHz, Chloroform-d) δ 7.31 (s, 4H), 7.26 (t, J = 2.7 Hz, 1H), 5.51 (s, 1H), 2.62 – 2.55 (m, 2H), 2.49 – 2.39 (m, 2H). 13C NMR (151 MHz, Chloroform-d) δ 209.66, 159.63, 147.54, 139.97, 133.68, 128.74, 127.86, 69.28, 35.33, 26.80. MS (EI): m/z calcd for C12H11ClO2: 222.04; found: 222.07.

2-((4-bromophenyl)(hydroxy)methyl)cyclopent-2-en-1-one (3c)

The crude product was purified by flash chromatography (PE:EA = 2:1) to give the product (104.8 mg, 26.2%). 1H NMR (400 MHz, Chloroform-d) δ 7.44 – 7.41 (m, 2H), 7.28 – 7.27 (m, 1H), 7.24 – 7.20 (m, 2H), 5.46 – 5.44 (m, 1H), 3.84 (d, J = 4.0 Hz, 1H), 2.57 – 2.54 (m, 2H), 2.41 – 2.38 (m, 2H). 13C NMR (101 MHz, Chloroform-d) δ 209.3, 159.5, 147.3, 140.4, 131.4, 128.0, 121.5, 68.8, 35.1, 26.6. MS (EI): m/z calcd for C12H11BrO2: 267.12; found: 266.97.

2-(hydroxy(4-methoxyphenyl)methyl)cyclopent-2-en-1-one (3d)

The crude product was purified by flash chromatography (PE:EA = 2:1) to give the product (37.5 mg, 11.5%). The spectral data are consistent with literature values43. 1H NMR (600 MHz, Chloroform-d) δ 7.30 – 7.27 (m, 3H), 6.88 – 6.85 (m, 2H), 5.48 (s, 1H), 3.78 (s, 3H), 3.48 (s, 1H), 2.59 – 2.56 (m, 2H), 2.45 – 2.42 (m, 2H). 13C NMR (151 MHz, Chloroform-d) δ 209.56, 159.2, 159.1, 147.9, 133.5, 127.6, 113.8, 69.4, 55.2, 35.2, 26.5. MS (EI): m/z calcd for C13H14O3: 218.09; found: 218.11.

2-(hydroxy(4-nitrophenyl)methyl)cyclohex-2-en-1-one (3e)

The crude product was purified by flash chromatography (PE:EA = 2:1) to give the product (47.1 mg, 12.7%). The spectral data are consistent with literature values43. 1H NMR (600 MHz, Chloroform-d) δ 8.15 (d, J = 8.8 Hz, 2H), 7.52 (d, J = 8.8 Hz, 2H), 6.83 (t, J = 4.2 Hz, 1H), 5.59 (d, J = 5.6 Hz, 1H), 3.67 (d, J = 5.8 Hz, 1H), 2.44 – 2.40 (m, 4H), 2.01–1.97 (m, 2H). 13C NMR (151 MHz, Chloroform-d) δ 200.0, 149.4, 148.1, 147.1, 140.1, 127.1, 123.4, 71.7, 38.3, 25.7, 22.3. MS (EI): m/z calcd for C13H13NO4: 247.08; found: 247.12.

2-(hydroxy(phenyl)methyl)cyclopent-2-en-1-one (3f)

The crude product was purified by flash chromatography (PE:EA = 2:1) to give the product (175 mg, 62.0%). The spectral data are consistent with literature values43. 1H NMR (400 MHz, Chloroform-d) δ 7.40–7.32 (m, 4H), 7.31–7.25 (m, 2H), 5.55 (s, 1H), 3.58 (brs, 1H), 2.59–2.56 (m, 2H), 2.45–2.42 (m, 2H).13C NMR (101 MHz, Chloroform-d) δ 209.5, 159.3, 147.7, 141.3, 128.4, 127.8, 126.3, 69.7, 35.2, 26.6. MS (EI): m/z calcd for C12H12O2: 188.23; found: 188.1.

2-(hydroxy(3-nitrophenyl)methyl)cyclopent-2-en-1-one (3j)

The crude product was purified by flash chromatography (PE:EA = 2:1) to give the product (136.8 mg, 39.1%).The spectral data are consistent with literature values43. 1H NMR (400 MHz, Chloroform-d) δ 8.24 (t, J = 2.0 Hz, 1H), 8.13 (ddd, J = 8.2, 2.4, 1.0 Hz, 1H), 7.74 (dt, J = 7.8, 1.3 Hz, 1H), 7.52 (t, J = 7.9 Hz, 1H), 7.35 (td, J = 2.7, 1.2 Hz, 1H), 5.65 (dd, J = 4.3, 1.8 Hz, 1H), 3.78 (d, J = 4.4 Hz, 1H), 2.65 – 2.62 (m, 2H), 2.48 – 2.45 (m, 2H). 13C NMR (101 MHz, Chloroform-d) δ 209.23, 159.9, 148.3, 146.7, 143.5, 132.5, 129.4, 122.7, 121.2, 68.9, 35.1, 26.8. MS (EI): m/z calcd for C12H11NO4: 233.22; found: 233.07.

3-(hydroxy(5-oxocyclopent-1-en-1-yl)methyl)benzonitrile (3 h)

The crude product was purified by flash chromatography (PE:EA = 2:1) to give the product (100.4 mg, 31.4%). 1H NMR (400 MHz, Chloroform-d) δ 7.68 (t, J = 1.7 Hz, 1H), 7.63 (dt, J = 7.8, 1.6 Hz, 1H), 7.56 (dt, J = 7.7, 1.5 Hz, 1H), 7.45 (t, J = 7.7 Hz, 1H), 7.32 (td, J = 2.7, 1.2 Hz, 1H), 5.57 (dd, J = 4.4, 1.8 Hz, 1H), 3.73 (d, J = 4.4 Hz, 1H), 2.64–2.61 (m, 2H), 2.47 – 2.44 (m, 2H). 13C NMR (101 MHz, Chloroform-d) δ 209.2, 159.7, 146.9, 142.9, 131.4, 130.8, 129.9, 129.2, 118.6, 112.5, 68.8, 35.1, 26.7. MS (EI): m/z calcd for C13H11NO2: 213.24; found: 213.1.

2-((2-fluoro-4-nitrophenyl)(hydroxy)methyl)cyclopent-2-en-1-one (3i)

The crude product was purified by flash chromatography (PE:EA = 2:1) to give the product (57.6 mg, 15.3%). 1H NMR (600 MHz, Chloroform-d) δ 8.08 (dd, J = 8.6, 2.1 Hz, 1H), 7.91 (dd, J = 9.7, 2.2 Hz, 1H), 7.80 (dd, J = 8.5, 7.2 Hz, 1H), 7.28 – 7.27 (m, 1H), 5.90 (d, J = 4.2 Hz, 1H), 4.13 (d, J = 5.0 Hz, 1H), 2.69 – 2.58 (m, 2H), 2.53 – 2.45 (m, 2H). 13C NMR (151 MHz, Chloroform-d) δ 209.7, 160.1, 158.8 (d, J = 251.7 Hz), 148.1 (d, J = 8.8 Hz), 144.6, 136.0 (d, J = 13.2 Hz), 128.7 (d, J = 4.3 Hz), 119.6 (d, J = 3.3 Hz), 111.1 (d, J = 27.1 Hz), 63.9 (d, J = 3.2 Hz), 35.1, 26.8. 19F NMR (565 MHz, Chloroform-d) δ -113.74. MS (EI): m/z calcd for C12H10FNO4: 251.21; found: 251.0.

2-((3-fluoro-4-nitrophenyl)(hydroxy)methyl)cyclopent-2-en-1-one (3 g)

The crude product was purified by flash chromatography (PE:EA = 2:1) to give the product (74.6 mg, 19.8%). 1H NMR (600 MHz, Chloroform-d) δ 8.04 – 8.01(m, 1H), 7.39 – 7.37(m, 2H), 7.31 (dd, J = 8.5, 1.6 Hz, 1H), 5.62 – 5.61 (m, 1H), 3.77 (d, J = 4.4 Hz, 1H), 2.66–2.64 (m, 2H), 2.48 – 2.46 (m, 2H). 13C NMR (151 MHz, Chloroform-d) δ 209.1, 160.2, 155.6 (d, J = 265.0 Hz), 150.5 (d, J = 7.6 Hz), 146.2, 136.4 (d, J = 7.4 Hz), 126.2, 122.1 (d, J = 3.4 Hz), 116.0 (d, J = 21.8 Hz), 68.3, 35.1, 26.8. 19F NMR (565 MHz, Chloroform-d) δ -116.54. MS (EI): m/z calcd for C12H10FNO4: 251.21; found: 251.0.

Conservation analysis of the residues

Using The online Consurf Server (https://consurf.tau.ac.il/) and protein structure display software Pymol to analyze the residues conservation of GkOYE.

Measurement the volume of catalytic pocket

The volume of catalytic pockets of different mutants was measured using DoSiteScorer in the on-line software PROTEINS PLUS44,45

Crystallization, refinement and model building

All initial conditions of crystallization were screened using the sitting drop vapor diffusion method with Hampton Research Crystal Screen Kits. The crystal of the apo-GkOYE.8 was obtained by optimization after 2 days at 20 °C in hanging-drop plates, under the conditions of mixing 0.8 μL protein solution (15 mg·mL–1) and an equal volume of reservoir solution (0.1 M glycine pH 9.0, 25% (w/v) polyethylene glycol 2000, 15% (w/v) glycerol). The crystal of the apo-GkOYE.8 is shown in Supplementary Fig. 6. The crystals were cryoprotected by transient soaking in reservoir solutions with an additional 20-25% glycerol, and the crystals were flash cooled in liquid nitrogen at 100 K for data collection. X-ray diffraction data were collected on a Bruker D8 QUEST diffractometer (Karlsruhe, Germany), and the data sets were indexed, integrated and merged using XDS. The crystal structure of the apo-GkOYE.8 was solved by the single anomalous scattering method using a crystal that was diffracted to a 3.11 Å resolution. The structure of the apo-GkOYE.8 was solved using the molecular replacement method with a CCP4 automatic. The protein structure of 3gr7 was used as a searching model. Structural refinement was achieved using the Coot46 and Refmac547 programs. The data collection and refinement statistics of the apo-GkOYE.8 crystal structure are listed in Supplementary Table 2 and have been deposited in the PDB under accession code 8X0J. Structural figures were prepared using PyMOL v2.3.3 (Schrödinger, LLC, New York, USA).

The secondary structure of key mutants detected by circular dichroism

Preparation of protein

The purified target protein is tested by SDS-PAGE for protein purity. When the target protein content reaches 95% or above (the higher the protein purity, the more reliable the experimental results), the purified protein can be used for circular dichroism spectroscopy. Circular dichroic determination using JASCO-1700 circular dichroic spectrometer made in Japan, the spectra of 190–240 nm in the far ultraviolet were determined at room temperature. The concentration of the sample was 0.2 mg·mL-1 and the radius of the sample cup was 0.1 cm. The resolution is 0.5 nm, the bandwidth is 0.5 nm, the sensitivity is 50 mdeg, and the speed is 0.8 nm·min-1. 0.1*PBS buffer was used for the background solution. In the process of sample determination, 0.1*PBS buffer was first measured as the background, and then the mutant protein after buffer replacement. The resulting spectrogram data was analyzed by Dichroweb.

Library construction and screening

The primer sequences used to generate DNA libraries are shown in Supplementary Data 1. Site-directed saturation mutation was performed by PCR using mutagenic primers and plasmid pET28a-GkOYE.8 as template according to the manufacturer’s instructions of QuickChange (Stratagene). The DpnI-digested PCR product of 3 μl was used to transform 80 μl of E. coli BL21(DE3) chemically competent cells and colonies after transformation were incubated for DNA sequencing until all the designed mutants were obtained. A single colony of recombinant E. coli strain was cultivated overnight (10–12 h, 37 °C) in LB medium with 50 μg·mL–1 kanamycin and used as the inoculum (1%). The culture was then transferred into 200 mL 2×YT medium containing appropriate antibiotics in a 500 ml flask. When the OD600 of the culture broth reached 0.6-0.8, isopropyl β-D-1-thiogalactopyranoside (IPTG) was added to a final concentration of 0.2 mM to induce gene expression. The cells were inducted at 16 °C for 16 h and collected by centrifugation (8000 × g, 10 min). The cell pellet was resuspended in 30 ml washing buffer containing a protease inhibitor and subsequently lysed by high pressure homogenizer. The lysed cells were incubated with DNase I (final concentration 0.1 mg·ml−1) for 30 min at 4 °C. After removing cell debris by centrifugation (10,000 r.p.m., 30 min, 4 °C). The cleared lysate was loaded on a Strep-Tactin column (Strep-Tactin Superflow high capacity), incubated for 60 min at 4 °C, and the protein was purified according to the manufacturer’s guidelines. Proteins were desalted using 10DG desalting columns (Bio-Rad) with PBS pH 10.0 and analysed by SDS–PAGE. Protein concentration of purified enzyme was measured by detecting absorbance at 280 nm using a NanoPhotometer N50 spectrophotometer and considering the calculated extinction coefficients with the ExPASy ProtParam Tool.3. All purification operations were conducted at 4°C when necessary. Then the pure protein of different mutants were carried out for conversion reaction. The reactions were performed in 300 μL PBS buffer (pH 10.0) with 5 mM 1, 1 mM 2, 100 μM purified protein and 3% methanol as cosolvent. Reactions were incubated at 25 °C and 220 rpm for 40 h. The reaction was terminated with equal volume of 1 M HCl, centrifuged at 14,000 × g for 10 min, filtered by 0.22 μm filter membrane, and then determined by HPLC.

Initial structural preparation for computational studies

The initial structure of GkOYE.8 were obtained by X-ray diffraction. The protonation states of the charged residues were determined at a constant pH of 10.0, based on pKa calculations via the H++ server (http://biophysics.cs.vt.edu/H++) and the consideration of the local hydrogen bonding network. In the GkOYE.7 models, residues His41, 44, 81, 95 and 167 were set as HIE, and residues His164, and 222 were set as HID. In the model, all Asp and Glu residues were deprotonated, while the Lys and Arg residues were protonated. The bond and angle force constants were determined using the Seminario method48, and point charge parameters for electrostatic potentials were determined using the ChgModB method. Each model was neutralized by the addition of Na+ ions and solvation in a truncated octahedral TIP3P water box with a buffer distance of 10 Å on each side. (R)-3 was optimized at the B3LYP-D3/6-31 G(d,p) level by using Gaussian 16, the partial charge of these ligands was fitted with HF/6-31 G(d) calculations and the restrained electrostatic potential protocol49 implemented by the Antechamber module in the Amber 18 package. The force field parameters for these ligands were adapted from the standard general Amber force field 2.0 (gaff2)50 parameters, while the standard Amber19SB force field was applied to describe the protein.

Molecular docking

To dock the (R)-3 to the active sites of the GkOYE.8, 50000 uniformly distributed snapshots from the 100-ns MD simulation (with time intervals of 2 ps) were selected and divided into ten groups using a hierarchical agglomerative (bottom-up) approach. The optimized substrate (R)-3 were docked to the active site of one representative group snapshot to mimic the ligand-protein complex. Molecular docking was performed with the Lamarckian genetic algorithm local search method using AutoDock Vina51. The docking approach was used for a rigid receptor conformation, while all rotatable torsion bonds of (R)-3 were left free. A grid box was centered near the residues 26, 164, 167 and 169, and its size was set at 20 × 20 × 20 Å with a spacing of 0.375 Å. A total of 500 independent docking runs were performed with a maximum energy evaluation of 2.5 × 107. The 500 docked conformations obtained were clustered with an RMSD of 2.0 Å and ranked using an energy-based scoring function. The possible catalytically active binding modes were selected as initial configurations to perform MD simulations of GkOYE.8 in complex with (R)-3, according to the scoring function and reasonable conformation.

MD simulations

All MD simulations were performed using the Amber 18 package software52. The MD pre-equilibrated GkOYE.8, and possible catalytically active binding modes of (R)-3 was used as initial conformations for MD simulations of the protein-ligand complexes. Each system was brought to equilibrium with a series of minimizations interspersed by short MD simulations, during which restraints on the heavy atoms of the protein backbone were gradually released (with force constants of 10, 2, 0.1, and 0 kcal [mol Å-2]) and then slowly heated from 0 to 300 K for 50 ps. Finally, a standard unrestrained 100-ns MD simulation with periodic boundary conditions at 300 K and 1 atm was performed. The pressure was maintained at 1 atm and coupled with isotropic position scaling. The temperature was maintained at 300 K using the Berendsen thermostat. Long-range electrostatic interactions were treated using the particle mesh Ewald method, and a cutoff of 12 Å was applied to both particle mesh Ewald9 and van der Waals interactions53. A time step of 2 fs was used along with the SHAKE algorithm for hydrogen atoms, and a periodic boundary condition was used. For each system, total of three replicas of 100 ns each were carried out, accumulating a total of 300 ns of simulation time. The conformations visited by the enzyme along all this simulation time were clustered based on protein backbone RMSD, and the most populated cluster was selected as a representative structure of these enzymes. The CPPTRAJ module was used to calculate the stability (structure, energy, and temperature variations), convergence (RMSD of the structures), distance, and angle of each system in the AmberTools18 software52.

DFT calculations

DFT calculations were performed using the Gaussian 16 package. All DFT structures were constructed based on the catalytic mechanism54 and combined with the reaction conditions in this study. In Fig. 4c, the reason we chose HPO42- as the nucleophilic reagent to attack substrate 1 is that in alkaline environments, the phosphate buffer pair (HPO42- and H2PO4–) in PBS buffer is mostly in the form of HPO42-.

In order to ensure the rigour of the experiment, the results were calculated simultaneously for H2PO4– as the nucleophilic reagent to attack substrate 1, as illustrated in Supplementary Fig. 11. Geometry optimizations of the minima and transition states involved were performed at the B3LYP-D3 level of theory with the 6-31 + G (d) basis set. Vibrational frequency calculations were performed at the same level to ensure that all stationary points were transition states (one imaginary frequency) or minima (no imaginary frequency) and to evaluate zero-point vibrational energies and thermal corrections at 298 K. Single-point energy calculations were performed at the B3LYP-D3 level using the 6-311 + G (2d, p) basis set. Solvation by water was considered using the CPCM model55 for all of the above calculations. All Supporting computational data can be found in the Supplementary Data 2. Optimized DFT structures are illustrated with CYLView (https://www.cylview.org/).

Reporting summary

Further information on research design is available in the Nature Portfolio Reporting Summary linked to this article.