• Physics 17, 137

Experiments reveal the factors that determine the friction between the single-atom-thick layers in van der Waals materials, which may have uses in lubrication technology.

Van der Waals (vdW) materials consist of stacked, single-atom-thick layers, and these layers can experience very low friction as they slide over one another, a property that might be exploited for lubrication. A research team has now distinguished several contributions to this low friction and has shown that effects at the edges of the sliding regions dominate [1]. Some of their experiments involved sliding a several-layer-thick flake across a surface made of a similar material containing a crack, which allowed the team to systematically control the edge length. The findings could guide efforts to engineer controllable frictional forces into such materials in micromechanical devices.

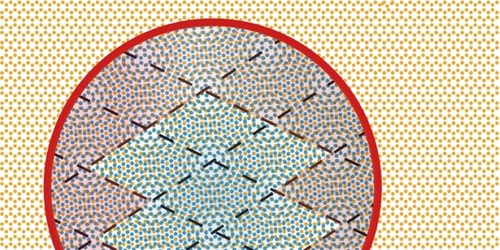

The very low friction, called superlubricity, exhibited by vdW materials has been previously shown to depend on the relative orientations of the layers. If one layer is rotated by some angle, called the twist angle, with respect to the layer below, the two layers form a “superlattice” in which the two atomic lattices fall periodically in and out of registry, like a pair of overlaid combs with slightly different spacings. This arrangement is called a Moiré pattern, and the repeating elements, or unit cells, of the superlattice are called Moiré tiles. Superlubricity arises because, in general, the contributions to the frictional force from the atoms within one Moiré tile cancel each other out: Some exert a push, while others exert a pull.

But the material structure cannot be infinitely large, and the friction is influenced by effects near the edges of the superlattice (the Moiré rim), where the Moiré tiles are incomplete and cancellation is imperfect [2]. Previous work has also shown that the atoms at the edge of a layer can contribute to the friction because they are easily pulled away from their equilibrium positions in the lattice and can “snag” as layers slide relative to one another [3]. Deducing the relative importance of all these contributions to the observed friction is challenging because it is hard to change the length of edges without also changing the surface area of the region of overlap between layers.

Wen Wang and colleagues at Southwest Jiaotong University in China have come up with an experimental method for teasing out the components of the friction between layers: surface area, Moiré rim, edges, and twist angle. Using an ion-beam etching technique, they made several-micrometer-diameter circular flakes of multilayer materials including graphene, boron nitride, and tungsten diselenide, each containing just a few layers. They placed a metal structure on top of each of these “sliders” and then used a microscale cantilever arm to drag each one over a surface of another vdW material—not always matching the slider material—while measuring the lateral resistance force.

To isolate the effects of edge atoms, the researchers dragged a slider over a naturally occurring crack in the underlying surface, introducing an extra “edge” in addition to the slider’s circular boundary. This procedure allowed them to vary the length of an edge—the portion of the crack under the slider—without changing the area of the slider. Wang and colleagues found that edge atoms make the most significant contribution to the frictional force.

They also found that the pressure pushing the two surfaces together affects the friction because this pressure can flatten out very slight ridges that develop at the interface. This effect leads to the counterintuitive result that, within a certain parameter range, friction decreases as the squeezing pressure increases.

The researchers also performed separate sliding experiments at various twist angles, without any cracks in the surface. Altering the twist changes the number and extent of incomplete Moiré tiles. These measurements showed that the frictional force for atoms in the rim region of the slider, where the Moiré tiles are incomplete, is around 1000 times greater than that for atoms within complete tiles.

Superlubricity in vdW materials might be valuable in micro- and nanomechanical devices such as sensitive force meters, where reducing friction and wear is critical, says Wang. “The ability to control friction by manipulating the Moiré superlattice opens up possibilities for designing surfaces with tailored lubrication behavior,” he says.

The work “sheds new light on the mechanisms underlying friction in superlubric interfaces,” says physical chemist Oded Hod of Tel Aviv University in Israel. “The authors show how twist angle and external pressure can be used as control parameters for friction” in vdW materials, Hod adds. “Understanding the underlying mechanisms is crucial for designing and controlling superlubric coatings and interfaces.”

–Philip Ball

Philip Ball is a freelance science writer in London. His latest book is How Life Works (Picador, 2024).

References

- Y. Li et al., “Contributions of edge and internal atoms to the friction of two-dimensional heterojunctions,” Phys. Rev. Lett. 133, 126202 (2024).

- E. Koren and U. Duerig, “Moiré scaling of the sliding force in twisted bilayer graphene,” Phys. Rev. B 94, 045401 (2016).

- Z. Guo et al., “Thermal-induced edge barriers and forces in interlayer interaction of concentric carbon nanotubes,” Phys. Rev. Lett. 107, 105502 (2011).