Scientists have created a new ‘biocooperative’ material based on blood, which has been shown to successfully repair bones, paving the way for personalized regenerative blood products that could be used as effective therapies to treat injury and disease.

Researchers from the Schools of Pharmacy and Chemical Engineering at the University of Nottingham have used peptide molecules that can guide key processes taking place during the natural healing of tissues to create living materials that enhance tissue regeneration. The research is published in Advanced Materials.

Most of our body tissues have evolved to regenerate ruptures or fractures with remarkable efficacy, as long as these are small in size. This healing process is highly complex. The initial stages rely on liquid blood forming the solid regenerative hematoma (RH), a rich and living microenvironment comprising key cells, macromolecules, and factors that orchestrate regeneration.

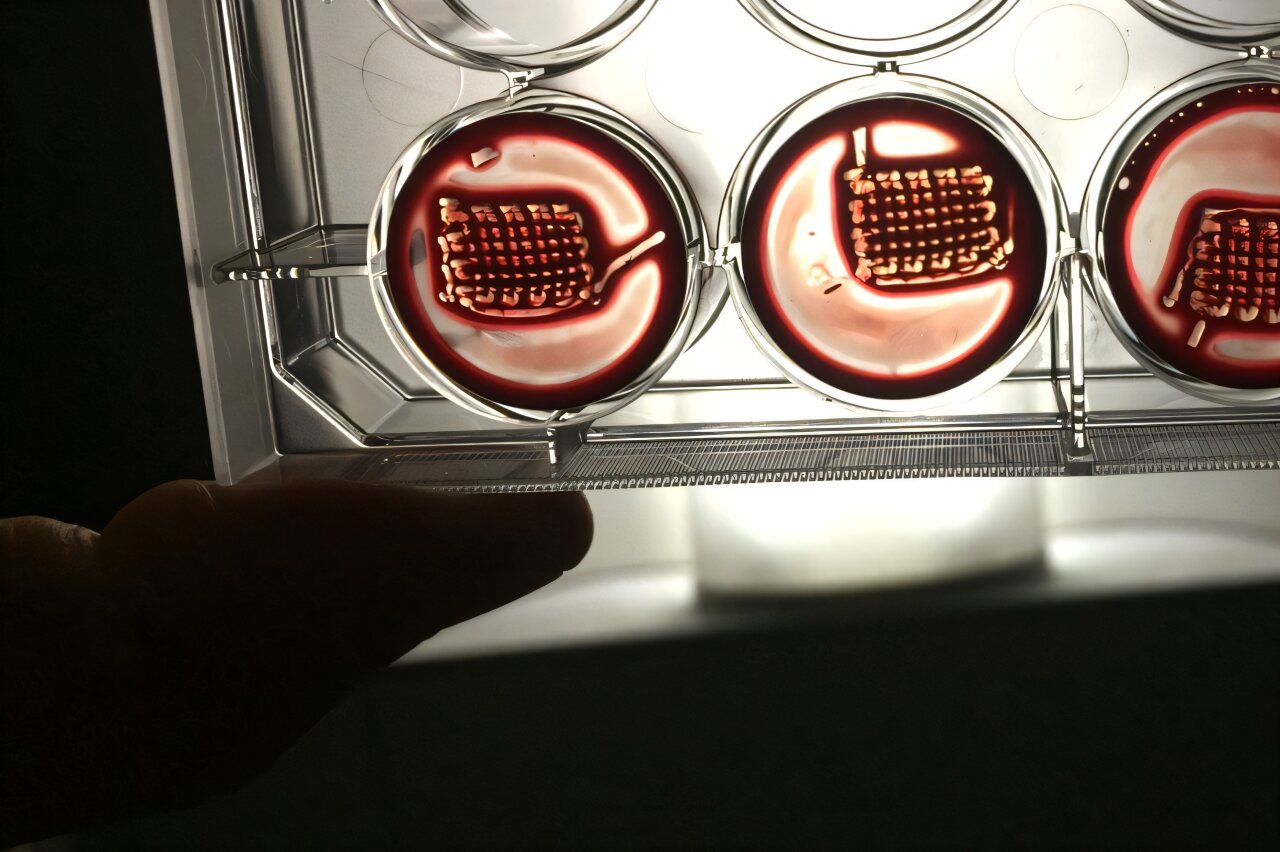

The team developed a self-assembling methodology where synthetic peptides are mixed with whole blood taken from the patient to create a material that harnesses key molecules, cells, and mechanisms of the natural healing process. In this way, it was possible to engineer regenerative materials capable of not only mimicking the natural RH, but also enhancing its structural and functional properties.

These materials can be easily assembled, manipulated, and even 3D printed while maintaining normal functions of the natural RH, such as normal platelet behavior, generation of growth factors, and recruitment of relevant cells important for healing. With this method, the team has shown the capacity to successfully repair bone in animal models using the animal’s own blood.

Alvaro Mata, who is Professor of Biomedical Engineering and Biomaterials in the School of Pharmacy and the Department of Chemical and Environmental Engineering at the University of Nottingham and led the study, said, “For years, scientists have been looking at synthetic approaches to recreate the natural regenerative environment, which has proven difficult given its inherent complexity. Here, we have taken an approach to try to work with biology instead of recreating it.

“This ‘biocooperative’ approach opens opportunities to develop regenerative materials by harnessing and enhancing mechanisms of the natural healing process. In other words, our approach aims to use regenerative mechanisms that we have evolved with as fabrication steps to engineer regenerative materials.”

Dr. Cosimo Ligorio from the Faculty of Engineering at the University of Nottingham is co-author on the study. He says, “The possibility to easily and safely turn people’s blood into highly regenerative implants is really exciting. Blood is practically free and can be easily obtained from patients in relatively high volumes.

“Our aim is to establish a toolkit that could be easily accessed and used within a clinical setting to rapidly and safely transform patients’ blood into rich, accessible, and tunable regenerative implants.”

More information:

Soraya Padilla‐Lopategui et al, Biocooperative Regenerative Materials by Harnessing Blood‐Clotting and Peptide Self‐Assembly, Advanced Materials (2024). DOI: 10.1002/adma.202407156

Provided by

University of Nottingham

Citation:

Scientists transform blood into regenerative materials, paving the way for personalized, 3D-printed implants (2024, November 17)

retrieved 17 November 2024

from https://phys.org/news/2024-11-scientists-blood-regenerative-materials-paving.html

This document is subject to copyright. Apart from any fair dealing for the purpose of private study or research, no

part may be reproduced without the written permission. The content is provided for information purposes only.